Page 228 - Softbound_Edition_19_en

P. 228

Solenoid operated spool valve

Solenoid operated spool valve Solenoid operated spool valve

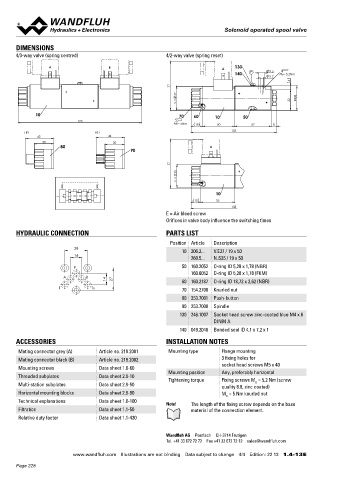

DIMENSIONS Solenoid operated spool valve with soft switching

4/3-way valve (spring centred) 4/2-way valve (spring reset) NG4

Flange construction ISO 4401-02

A B A 130 ◆ 4/3-way with spring centred mid position

140 E 9.5 MD= 5.2Nm ◆ 4/2-way with spring reset

5.2 Q = 20 l/min

6 ◆ max

77 ◆ p = 350 bar

max

37 38

V = 32

DESCRIPTION APPLICATION

10 70 60 10 50 Direct operated solenoid spool valve with 4 connections in 5 cham- Normal solenoid spool valves switch very quickly. This can lead to

193

MD= 5Nm 18 50 57 8 ber design. With the solenoids deenergised, the spool is held in the shocks in the hydraulic system which can cause mechanical wear

133 center position by the spring (4/3), or switched back to the offset and have a negative effect on operation. The soft switching valves

HF1 HS1

43 44 position (4/2). The soft switching of the valve is achieved by means slow down and dampen the switching movements which benefits

30 30 of an optimum combination of the orifice and spool design. Precise the system. Optimum results can be achieved if all 4 connections

80 A

90 spool fit, low leakage, long service life time. Spool made from are connected and the valve is properly vented. Miniature values

hardened steel, valve body from high quality hydraulic cast steel. are used where both, reduced dimensions and weight are import-

77 Wide range of standard and special voltages. ant.

35

N =

10 SYMBOL

15 53 AB1 AB2

133 A B

E = Air bleed screw

Orifices in valve body influence the switching times a a b b a a b b

HYDRAULIC CONNECTION PARTS LIST P T

Position Article Description ACB AC1 CB2

28 10 206.2... V.E37 / 19 x 50 A B A B A B

14

260.5... N.S35 / 19 x 50 a 0 b a b

P 50 160.2052 O-ring ID 5,28 x 1,78 (NBR) a b a b

160.6052 O-ring ID 5,28 x 1,78 (FKM) P T P T P T

A B

14 27 60 160.2187 O-ring ID 18,72 x 2,62 (NBR) ADB AD1 DB2

T T0 70 154.2700 Knurled nut A B A B A B

80 253.7001 Push-button 0

a b a b

90 253.7000 Spindle a b a b

130 246.1007 Socket head screw zinc-coated blue M4 x 6 P T P T P T

DIN84 A

140 049.2040 Bonded seal ID 4,1 x 7,2 x 1

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

ACCESSORIES INSTALLATION NOTES

Designation 4/2-, 4/3-spool valve Working pressure p = 350 bar

Mating connector grey (A) Article no. 219.2001 Mounting type Flange mounting Construction Direct operated Tank pressure p max = 100 bar

T max

Mating connector black (B) Article no. 219.2002 3 fixing holes for Mounting Flange construction Maximum volume flow Q = 20 l/min, see characteristics

max

Mounting screws Data sheet 1.0-60 socket head screws M5 x 40 Nominal size NG4 according to ISO 4401-02 Leakage oil See characteristics

Mounting position Any, preferably horizontal

Threaded subplates Data sheet 2.9-10 Tightening torque Fixing screws M = 5,2 Nm (screw Actuation Switching solenoid Fluid Mineral oil, other fluid on request

D

Multi-station subplates Data sheet 2.9-50 quality 8.8, zinc coated) Ambient temperature -25…+70 °C Viscosity range 12 mm /s…320 mm /s

2

2

Horizontal mounting blocks Data sheet 2.9-90 M = 5 Nm knurled nut if > +50 °C, then no undervoltage is Temperature range -25…+70 °C (NBR)

D admissible

Technical explanations Data sheet 1.0-100 fluid -20…+70 °C (FKM)

Note! The length of the fixing screw depends on the base Weight 0,90 kg (1 solenoid) Contamination Class 18 / 16 / 13

Filtration Data sheet 1.1-50 material of the connection element. 1,25 kg (2 solenoids) efficiency

Relative duty factor Data sheet 1.1-430

MTTFd 150 years Filtration Required filtration grade ß 10…16 ≥ 75,

see data sheet 1.0-50

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 22 13 1.4-13 E www.wandfluh.com Illustrations are not binding Data subject to change 1/4 Edition: 22 09 1.4-23 E

Page 228