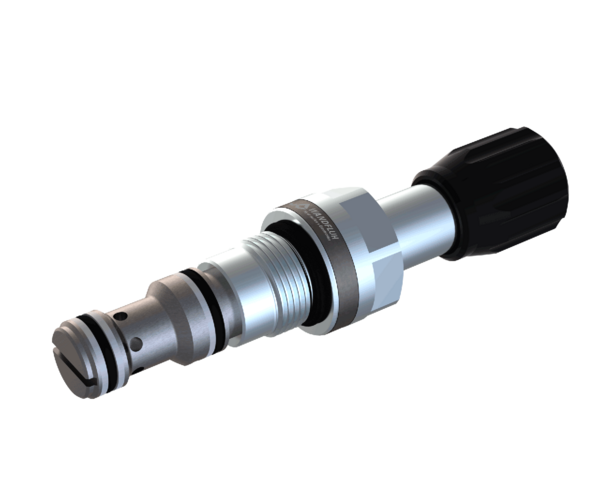

Pressure relief, backpressure, pressure sequence, accumulator unloading valves M22x1,5

Pilot operated accumulator unloading valve in screw-in cartridge construction for cavity according to ISO 7789. The valve has an adjustable upper switching point and a switching pressure difference which is fixed by the design. If the pressure in P exceeds the upper, adjustable switching pressure, the pilot control is opened by the pilot control spool. A pilot oil flow passes, and the reverse side of the main spool is unloaded. The produced pressure difference shifts the main spool against the spring, and the valve switches to unloading circuit. Due to the surface difference in the pilot control part, the pilot oil flow is interrupted, as soon as the pressure in the accumulator drops by 15 %, resp. 25 % of the upper switching point. Pressures at the main spool balance out, and the spring shifts the main spool into the closed position. The pump can now again build up the system presssure up to the upper switching point, the cycle starts again.

Accumulator loading cartridge

- pilot operated

- pmax = 400 bar

- pN max = 350 bar

- Qmax = 30 l/min

Application

Accumulator unloading valves are used in hydraulic systems with pressure accumulators. They allow an energy and cost-saving system design in the case of strongly varying oil requirement of cylinders, or for maintaining pressures over a period of time, e.g. in the case of clamping procedures. The screw-in cartridge is perfectly suitable for installation in control blocks and is installed in sandwich- (vertical stacked systems) and in flange plates (corresponding data sheets in this register). For machining the cartridge cavity in steel and aluminum blocks, cavity tools are available (hire or purchase). Please refer to the data sheets in register 2.13. Note: An additional pressure relief valve must be present for the system protection. Please observe the adjustment and connection example in the „Symbol” section.