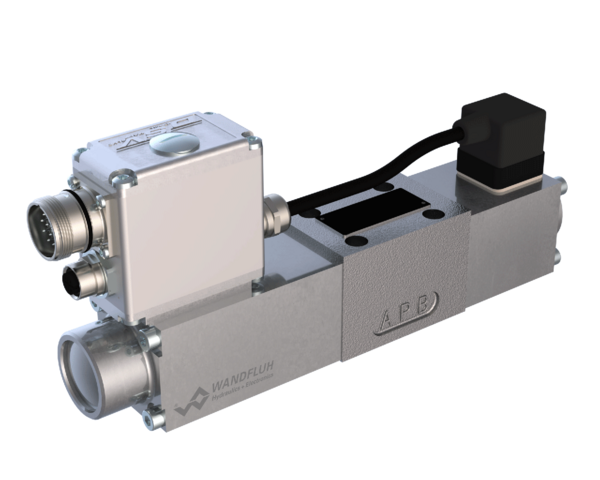

Proportional spool valves NG6

Direct operated proportional spool valve with 4 connections in 5-chamber system. With the integrated spool position sensor (LVDT), the actual position of the spool is continuously recorded and made to follow the transmitted command value. By means of this internal position control, a minimum hysteresis and excellent dynamic characteristics are assured. The Plug & Play valves are factory set and adjusted and have therefore a high valve-to-valve reproducibility. With protection class IP67 for the electronics, these valves are suitable for harsh environmental conditions. Proportional to the electronically transmitted command value, the spool stroke, the spool opening and the valve volume flow increase. The control takes place via an analogue interface or a fieldbus interface (CANopen, J1939 or Profibus DP). The parameterisation takes place by means of the free of cost parameterisation and diagnostics software «PASO» or via fieldbus interface. The USB parameterisation interface is accessible through a screw plug. «PASO» is a Windows program in the flow diagram style which enables the intuitive setting and storing of all variable parameters. The data remain saved in case of a power failure and can also be reproduced and transferred to other DSVs. As an option, these valves are available with integrated controller. As feedback value generators sensors with voltage or current output can be connected directly. The available controller structures are optimised for applications with hydraulic actuations.

Proportional spool valve with integrated electronics

and spool position control with LVDT

Flange construction

- direct operated

- Qmax = 50 l/min

- QN max = 40 l/min

- pmax = 350 bar

Application

Proportional spool valves are perfectly suitable for demanding tasks due to the high resolution, large volume flow and low hysteresis. They are used where good valve–to–valve reproducibility, easy installation, comfortable operation and high precision are very important. The integrated controller reliefs the machine control and operates the axis (position, angle, pressure, etc.) in a closed control loop. The applications are in the industry as well as in the mobile hydraulics for the smooth control of hydraulic actuators. Some examples: control of the rotor blades of wind generators, forestry and earth moving machines, machine tools and paper production machines, simple position controls, robotics and fan control.

![[Translate to English:] Regler Verstärker Elektronik Hydraulik Ventile](/fileadmin/_processed_/5/7/csm_SD73_2__d76dc1d4cf.png)