Page 214 - Softbound_Edition_19_en

P. 214

Solenoid operated spool valve

Solenoid operated spool valve Solenoid operated spool valve

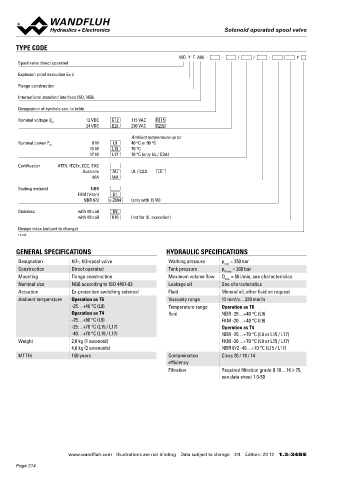

TYPE CODE ELECTRICAL SPECIFICATIONS SURFACE TREATMENT

WD Y F A06 - - / / - # Protection class IP65 / 66 / 67 -The valve body, the cover and the socket head screws are made of

Spool valve direct operated Relative duty factor 100 % DF stainless steel

-The slip-on coil and the armature tube are zinc nickel coated

Explosion proof execution Ex d Switching frequency 12'000 / h Optionally K10:

Voltage tolerance ± 10 % with regard to nominal voltage -The coil is made of stainless steel

Flange construction Standard nominal 12 VDC, 24VDC, 115 VAC, 230 VAC

voltage AC = 50 to 60 Hz ± 2 %, with built-in

International standard interface ISO, NG6 SEALING MATERIAL

two-way rectifier

Designation of symbols acc. to table Standard nominal 9 W, 15 W, 17 W NBR or FKM (Viton) as standard, choice in the type code

power

Nominal voltage U N 12 VDC G12 115 VAC R115 INBETRIEBNAHME

24 VDC G24 230 VAC R230 Temperature class Nominal power 9 W: T1…T6 The solenoid coil must only be put into operation, if the

Nominal power 15 W / 17 W: T1…T4 Attention!

Ambient temperature up to: Other electrical specifications see data sheet 1.1-183, requirements of the operating instructions supplied are

Nominal power P N 9 W L9 40 °C or 90 °C Note! observed to their full extent. In case of non-observance,

15 W L15 70 °C 1.1-183S and 1.1-184 no liability can be assumed.

17 W L17 70 °C (only UL / CSA)

Certification ATEX, IECEx, CCC, EAC PERFORMANCE SPECIFICATIONS

Australia AU UL / CSA UL 2

MA MA Oil viscosity u = 30 mm /s

p = f (Q) Performance limits p = f (Q) Performance limits L9

Sealing material NBR Measured with nominal voltage -10% Measured with nominal voltage -10%

FKM (Viton) D1

NBR 872 y-Z604 (only with 15 W) at 50 °C (steady-state temperature) at 40 °C (steady-state temperature)

Execution L9 90 °C on request

Stainless with K8 coil K9

with K9 coil K10 (not for UL execution) p [bar] AB1 / AB2 ADB ACB AB3/BEA p [bar] ADB ACB AB3

350 K4196 350 K4197

Design index (subject to change) 300 300

1.3-34S 250 250 AB1 / AB2

200 200

150 150

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS 100 100

50 50

Designation 4/2-, 4/3-spool valve Working pressure p = 350 bar

max 0 Q [l/min] 0 Q [l/min]

Construction Direct operated Tank pressure p = 200 bar 0 10 20 30 40 50 0 5 10 15 20 25 30

T max

Mounting Flange construction Maximum volume flow Q = 50 l/min, see characteristics

max

Nominal size NG6 according to ISO 4401-03 Leakage oil See characteristics

Actuation Ex-protection switching solenoid Fluid Mineral oil, other fluid on request Δp = f (Q) Pressure drop volume flow characteristic Volume flow direction

Ambient temperature Operation as T6 Viscosity range 12 mm /s…320 mm /s per control edge Symbol P-A P-B P-T A-T B-T

2

2

-25…+40 °C (L9) Temperature range Operation as T6 p [bar] AB1 / AB3 2 2 - 3 3

Operation as T4 fluid NBR -25…+40 °C (L9) 20 K4291 4 ACB 1 1 - 2 2

-25…+90 °C (L9) FKM -20…+40 °C (L9) 18 3 ADB 1 1 - 1 1

16

-25…+70 °C (L15 / L17) Operation as T4 14 2 1

12

-40…+70 °C (L15 / L17) NBR -25…+70 °C (L9 or L15 / L17) 10 BEA 1 1 4 2 2

Weight 2,8 kg (1 solenoid) FKM -20…+70 °C (L9 or L15 / L17) 8 6

4,6 kg (2 solenoids) NBR 872 -40…+70 °C (L15 / L17) 4 2

L

MTTFd 150 years Contamination Class 20 / 18 / 14 0 0 5 10 15 20 25 30 35 40 45 50 Q [l/min] Q = f (Q) Leakage volume flow characteristics

P → T

efficiency

3

Filtration Required filtration grade ß 10…16 ≥ 75, Q [cm /min]

L

see data sheet 1.0-50 300 K4199

250

Note! With the L15 / L17 execution for ambient temperatures BEA

up to 70 °C, the performance specifications have been 200

evaluated with an ambient temperature of 50 °C 150 AB1 / AB2

100 AB3

Attention! For valves for the temperature ranges „-40 °C to…” 50 ACB / ADB

(Z604) the leakage volume flow can be up to eight times 0 p [bar]

higher. 0 50 100 150 200 250 300 350

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 23 12 1.3-34S E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 23 12 1.3-34S E

Page 214