Page 206 - Softbound_Edition_19_en

P. 206

Solenoid operated spool valve

Solenoid operated spool valve Solenoid operated spool valve

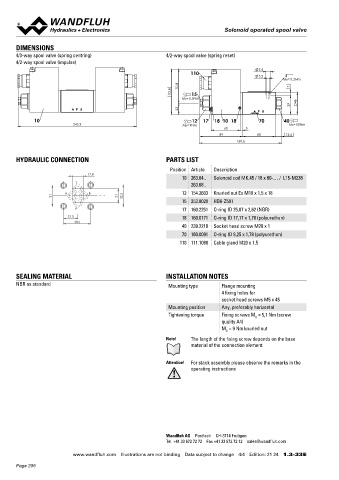

DIMENSIONS Solenoid operated spool valve

4/3-way spool valve (spring centring) 4/2-way spool valve (spring reset) Flange construction NG6

4/2-way spool valve (impulse) ISO 4401-03

◆ 4/2-way impulse valve

9.5

110 ◆ 4/3-way with spring centred mid position x II 2 G Ex db IIC T6, T4

5.2

MD= 5.2Nm ◆ 4/2-way with spring reset x II 2 D Ex tb III C T80 °C, T130 °C

70.8 7 ◆ Q = 80 l/min x I M2 Ex db I Mb

max

93.8 15 ◆ p = 350 bar Class I Division 1

max

MD=5.5Nm 46 Class I Zone 1

39

23

10 12 17 18 10 18 70 40

245.9 MD=9Nm MD=50Nm

60 5 DESCRIPTION APPLICATION

89 68 12.6 Direct operated solenoid spool valve with 4 connections in 5 cham- These valves are suitable for applications in explosion-hazard

169.6 ber design. With the solenoids deenergised, the spool is held in the areas, open cast and also in mines. Spool valves are mainly used for

center position by the spring (4/3), or switched back to the offset controlling direction of movement and stopping of hydraulic cylin-

HYDRAULIC CONNECTION PARTS LIST position (4/2). With the impulse spool (4/2), the spool is held in the ders and motors. The direction of movement is determined by the

Position Article Description switching position by the detent. The pressure tight encapsulated position of the spool and its symbol.

17.8 Ex-protection solenoid coil prevents an explosion on the inside

10 263.64.. Solenoid coil MK.45 / 18 x 60-… / L15-M238 penetrating to the outside as well as an ignitable surface tempera-

T 263.68.. ture.

A B 12 154.2603 Knurled nut Ex M18 x 1,5 x 18

31 21 32.5 CERTIFICATES ACTUATION

15 253.8028 HB6-Z591

P 17 160.2251 O-ring ID 25,07 x 2,62 (NBR) Surface Mining Standard Z604 Actuation Switching solenoid, wet pin push type,

21.5 18 160.0171 O-ring ID 17,17 x 1,78 (polyurethan) -25 °C to… -40 °C to… pressure tight

40.5 ATEX x x x x Execution MKY45 / 18x60 (data sheet 1.1-183)

40 239.2210 Socket head screw M20 x 1 MKU45 / 18x60 (data sheet 1.1-184)

70 160.0091 O-ring ID 9,25 x 1,78 (polyurethan) IECEx x x x x Connection Cable gland for cable Ø 6,5…14 mm

CCC x x x x

110 111.1080 Cable gland M20 x 1,5

EAC x x x x Attention! The UL execution is always supplied without cable

gland

Australia x x x x

MA x x

SEALING MATERIAL INSTALLATION NOTES UL / CSA x x x

NBR as standard Mounting type Flange mounting The certificates can be found on www.wandfluh.com

4 fixing holes for

socket head screws M5 x 45

Mounting position Any, preferably horizontal SYMBOL

Tightening torque Fixing screws M = 5,1 Nm (screw

D

quality A4) AB3 AB1 AB2

M = 9 Nm knurled nut A B A B A B

D

Note! The length of the fixing screw depends on the base a a b b a a b b a a b b

material of the connection element. P T P T P T

Attention! For stack assembly please observe the remarks in the ACB AC1 CB2

operating instructions A B A B A B

a o b a b a b

a b a b a b

P T P T P T

ADB AD1 DB2

A B A B A B

o b a

a b a b

a b a b a b

P T P T P T

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 21 24 1.3-33 E www.wandfluh.com Illustrations are not binding Data subject to change 1/5 Edition: 21 05 1.3-34 E

Page 206